Mastering Gearbox Syncro: Understanding Its Functionality and Importance in Transmission Systems

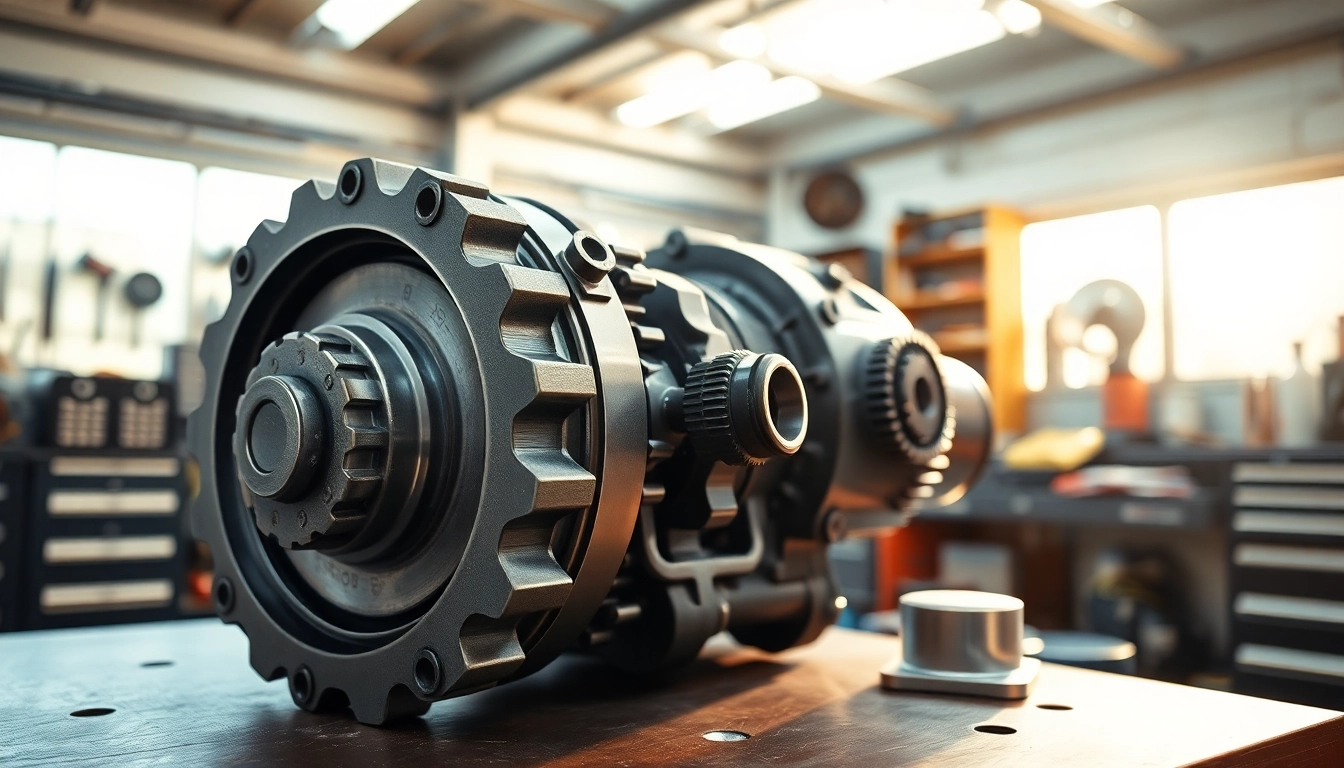

Introduction to Gearbox Syncro

The gearbox syncro, often referred to as a synchronizer, plays a crucial role in modern transmission systems, ensuring a smooth transition between gears. Understanding the function and importance of gearbox syncros can significantly enhance your knowledge of automotive transmissions, whether you’re a car enthusiast, a mechanic, or just someone who wants to grasp the inner workings of their vehicle. Gearbox syncros enable seamless gear shifts, allowing drivers to change gears without causing excessive wear and tear on their vehicles. For more extensive information on gearbox syncro technologies, you might refer to gearbox syncro resources available online.

What is a Gearbox Syncro?

At its core, a gearbox syncro is a mechanical component within a vehicle’s transmission that facilitates the engagement of gears. It allows the input shaft and the output shaft to synchronize their speeds, ensuring a smooth connection when shifting gears. This mechanism is especially important in manual transmissions, where the driver relies on the physical connection between gears. By matching the speeds of the gears, synchros help prevent grinding and excessive wear during shifts.

How Does Gearbox Syncro Work?

The operation of a gearbox syncro hinges on a series of friction components. When a driver engages the gear shift, the syncro works by pressing against the gear to synchronize its speed with that of the input shaft. Once the speeds are matched, a lock engagement occurs, allowing the gear to be fully engaged without any grinding or resistance. Typically, this process involves several components, including a hub, cone, and blocker ring, which interact to create a snug fit between the gears.

The Role of Gearbox Syncro in Transmissions

Syncros serve as the unsung heroes of manual transmission systems. They assist not just in shifting but also in providing feedback to the driver. A properly functioning syncro ensures that the transition between gears feels seamless and fluid, enhancing the overall driving experience. Additionally, syncros play a vital part in reducing the stress on the transmission system as a whole, helping to extend the lifespan of various components by minimizing wear-related issues.

Types of Gearbox Syncros

Commonly Used Syncro Designs

There are several designs of gearbox syncros commonly found in vehicles today. The most prevalent types include:

- Double Cone Syncros: These consist of two cone shapes that help in establishing smoother gear engagement, especially under high load scenarios.

- Single Cone Syncros: Often used in lighter vehicles, these syncros feature a single cone shape but still manage to deliver effective performance in gear shifts.

- Baulk Ring Syncros: This design utilizes a baulk ring which helps to guide the synchronization process by allowing gears to engage only when their speeds match.

Material Variations in Syncros

The materials used in the construction of gearbox syncros can have a dramatic effect on their performance and longevity. Common materials include:

- Steel: Known for its strength and durability, steel syncros are often used in performance vehicles where high torque is common.

- Sintered Bronze: This material offers excellent friction properties and is widely employed due to its energy-absorbing capabilities.

- Composite Materials: Recently, advancements in technology have led to the development of composite materials that provide lower weight and enhanced performance.

Advantages of Different Gearbox Syncros

Each type of gearbox syncro design and material presents unique advantages. For instance:

- Double cone syncros offer better efficiency during shifting, particularly under heavy loads.

- Baulk ring syncros minimize the risk of gear clash, providing a more user-friendly driving experience.

- Sintered bronze syncros reduce the wear on gears, extending their operational life.

Common Issues with Gearbox Syncros

Signs of a Failing Gearbox Syncro

A malfunctioning gearbox syncro can lead to various issues that significantly affect your vehicle’s performance. Common signs of a failing syncro include:

- Grinding Noises: This often occurs during gear shifts, signaling that the gears aren’t meshing properly.

- Difficulty Shifting Gears: If you notice resistance when attempting to shift, it may indicate syncro failure.

- Slipping Gears: If the vehicle unexpectedly pops out of gear, the syncros could be unable to hold the gears together properly.

Troubleshooting Gearbox Syncro Problems

Identifying the root cause of gearbox syncro issues typically involves a systematic troubleshooting process. Start by:

When to Replace a Gearbox Syncro

Knowing when to replace a gearbox syncro can save you from further, more costly transmission repairs. Consider replacing your syncros when:

- Grinding becomes consistent during gear shifts.

- You experience frequent gear slippage, particularly under acceleration.

- Visual inspections reveal significant wear or damage to the syncro components.

Maintenance Tips for Gearbox Syncros

Regular Inspection Routines

Establishing a regular maintenance routine is critical for extending the life of your gearbox syncros. Ensure you conduct inspections that include:

- Checking for any signs of leakage around the gearbox.

- Testing gear shifting under various driving conditions to identify irregularities.

- Regularly monitoring transmission fluid levels and quality.

Recommended Lubricants and Fluids

Using the right lubricant is essential to keep your gearbox syncros operating smoothly. High-quality transmission fluids specifically designed for your vehicle’s specifications will reduce friction and wear. Always refer to your vehicle’s owner’s manual for the manufacturer’s recommendations, and consider synthetic fluids for optimal performance.

How Proper Maintenance Improves Longevity

Consistent and effective maintenance plays a vital role in prolonging the life of your gearbox syncros. By addressing minor issues promptly, ensuring that fluid levels are adequate, and using the correct lubricants, you can significantly enhance the durability and reliability of your transmission system.

Future of Gearbox Syncro Technology

Innovations in Syncro Design

As automotive technology continues to evolve, the design of gearbox syncros is also advancing. Innovations such as digital synchronization and electric assist technologies are emerging, allowing for even smoother shifts and reduced latency in gear changes. This evolution not only improves vehicle performance but also paves the way for more efficient energy use in terms of powertrain management.

Impact of Electric Vehicles on Gearbox Syncros

The rise of electric vehicles (EVs) presents a new frontier for gearbox syncro technology, as many EVs utilize single-speed transmissions bypassing traditional gear shift mechanisms altogether. However, hybrid vehicles and performance EVs may still incorporate syncros to optimize power delivery and performance across varying driving conditions. Efficiency and reliability will be driving factors in the evolution of syncros in the era of electrification.

Upcoming Trends in Transmission Systems

Future trends in transmission technology suggest a move towards even more integrated and intelligent systems. Advances in AI and machine learning are paving the way for smart transmissions capable of predicting driver intentions and adapting accordingly. This may lead to more responsive and adaptive syncros that provide an effortless driving experience.

Leave a Reply